Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Predicting Shelf-Life of Fruits: A Multifactorial Approach using Intrinsic and Extrinsic Determinants

Authors: Sowmiya R, Sujana Chanstar T, Safiya Banu S, Arun Kumar R

DOI Link: https://doi.org/10.22214/ijraset.2024.59163

Certificate: View Certificate

Abstract

Predicting the shelf life of fruits is crucial for maintaining food freshness and reducing waste in the supply chain. This paper presents a novel approach to predicting fruit shelf life using a combination of fruit characteristics and environmental factors. Firstly, the freshness of fruits is assessed based on their physical attributes such as size, shape, and color. Next, a predictive model is developed to estimate the number of days a fruit remains edible in a given cold storage system, considering temperature variations. The proposed method leverages machine learning techniques to analyze historical data and identify patterns that influence fruit degradation over time. Experimental results demonstrate the effectiveness of the proposed approach in accurately predicting fruit shelf life, thus facilitating better inventory management and reducing food wastage. This research contributes to the optimization of fruit storage practices, ultimately leading to improved food quality and sustainability in the agricultural sector.

Introduction

I. INTRODUCTION

Food waste is a significant global challenge, with the Food and Agriculture Organization (FAO) estimating that one-third of all food produced globally is lost or wasted each year [1]. Fruits are particularly susceptible to spoilage due to their highwater content and rapid respiration rates [2]. Minimizing fruit waste within the supply chain requires accurate methods for assessing freshness and predicting shelf life.

Traditional methods for fruit freshness assessment rely on visual inspection by human experts. However, these methods are subjective and prone to human error [3]. Additionally, external factors such as storage temperature significantly impact fruit shelf life [4]. Therefore, a more robust and objective approach is needed to predict fruit shelf life and optimize storage conditions.

This project presents a novel two-step approach for predicting the remaining shelf life of fruits. The first step utilizes machine learning to assess fruit freshness based on visual characteristics like size, shape, and color. The second step integrates the predicted freshness level with the storage temperature of a cold storage system to estimate the remaining edible days for the fruit. This combined approach leverages the power of computer vision and environmental control to provide a more accurate prediction of fruit shelf life, ultimately contributing to reduced food waste and improved efficiency within the fruit supply chain.

II. BACKGROUND

The global fruit market is projected to reach $2.4 trillion by 2025, driven by rising consumer demand for fresh produce [5]. This growth necessitates efficient management practices throughout the supply chain to minimize losses and ensure product quality. Fruit spoilage remains a significant challenge, with one-third of all fruits produced globally lost or wasted each year [6]. Traditional methods of fruit freshness assessment, based on visual inspection, are subjective and labour-intensive. Additionally, these methods do not account for the impact of storage conditions on shelf life.

A. Limitations of Traditional Methods

- Subjectivity: Human inspectors can have varying interpretations of freshness based on experience and individual perception.

- Inconsistency: Freshness evaluations can vary depending on the inspector and the specific fruit being assessed.

- Labor-intensive: Visual inspection requires dedicated personnel, increasing operational costs.

- Time-consuming: Inspecting large quantities of fruit can be slow and inefficient.

B. Factors Affecting Fruit Shelf Life

Fruit shelf life is influenced by a combination of intrinsic and extrinsic factors. Intrinsic factors include the fruit's variety, maturity stage, and physiological characteristics. Extrinsic factors encompass storage temperature, humidity, and atmospheric composition.

- Intrinsic Factors: Variety, maturity, and physiological properties of the fruit itself.

- Extrinsic Factors: Storage temperature, humidity, and the surrounding atmosphere (e.g., presence of ethylene gas).

C. Benefits of Machine Learning and Computer Vision

- Objectivity: Machine learning algorithms provide objective assessments based on data analysis, reducing subjectivity and human error.

- Efficiency: Automated image acquisition and analysis through computer vision significantly improves assessment speed.

- Scalability: These technologies can be readily scaled to handle large volumes of fruit, making them suitable for commercial applications.

- Data-driven Insights: Machine learning models can identify complex patterns in fruit characteristics that may not be readily apparent through visual inspection, leading to a deeper understanding of factors influencing shelf life.

D. Need for Improved Shelf-Life Prediction

Traditional methods of fruit freshness assessment have limitations. A more objective and robust approach is needed to accurately predict shelf life and minimize fruit waste within the supply chain. This project addresses this need by developing a novel two-step approach that leverages machine learning and computer vision to predict fruit shelf life. This project leverages the power of machine learning and computer vision to develop a novel two-step approach for predicting fruit shelf life. This approach has the potential to revolutionize fruit quality control within the supply chain, minimizing food waste and optimizing storage practices.

III. RELATED WORK

A. Machine Learning and Computer Vision for Fruit Freshness Assessment and Shelf-Life Prediction

Fruit spoilage is a significant economic and environmental concern. The Food and Agriculture Organization (FAO) estimates that one-third of all food produced globally is lost or wasted each year, with fruits being particularly susceptible due to their highwater content and rapid respiration rates. Minimizing fruit waste necessitates robust methods for assessing freshness and predicting shelf life. Traditional methods, reliant on visual inspection by human experts, are subjective, labor-intensive, and prone to error.

Recent advancements in machine learning (ML) and computer vision (CV) offer promising solutions for objective and efficient fruit freshness assessment and shelf-life prediction. This section explores relevant research areas, highlighting key techniques, features considered, and potential benefits.

- Machine Learning for Fruit Freshness Assessment

Machine learning algorithms excel at analyzing large datasets to identify patterns and relationships. In fruit freshness assessment, these algorithms analyze fruit image data to identify features indicative of freshness. Common techniques include:

a. Convolutional Neural Networks (CNNs): Deep learning models adept at recognizing patterns in visual data. Studies like utilize CNNs for apple ripeness classification based on image features like color variations.

b. Support Vector Machines (SVMs): Effective for classification tasks. Research by employs SVMs to classify citrus fruit quality based on color and texture features extracted from images.

2. Features Used in Machine Learning for Fruit Freshness Assessment

a. Color Features: Mean, standard deviation, and distribution of various color channels (RGB, HSV, Lab*) can indicate ripeness or spoilage.

b. Texture Features: Statistical measures like smoothness, roughness, and entropy derived from image texture analysis can reveal blemishes or decay.

c. Shape Features: Geometric properties like aspect ratio, circularity, and diameter can be informative for certain fruits.

3. Computer Vision for Fruit Quality Inspection

Computer vision techniques automate image acquisition and analysis, improving efficiency and consistency in fruit quality control. Deep learning algorithms play a significant role in this area:

a. Object Detection: Algorithms like YOLOv3 can automatically detect defects like blemishes, bruises, and cracks on fruit surfaces, impacting shelf life.

b. Image Segmentation: Techniques like semantic segmentation can identify and classify specific regions within a fruit image, aiding in defect detection and disease identification.

4. Sensor-based Shelf-Life Prediction

Non-destructive sensors offer an alternative approach, measuring various fruit properties like:

a. Firmness: Measured using penetrometers, firmness provides valuable insights into ripeness and potential shelf life.

b. Maturity: Spectroscopic sensors can assess maturity by measuring specific wavelengths of light absorbed or reflected by the fruit.

c. Respiration Rate: Measures the rate of oxygen consumption, indicating fruit metabolic activity and potential spoilage risk.

5. Integration of Machine Learning and Environmental Data

While the previous approaches focus on fruit characteristics, some research explores combining these techniques with environmental data:

a. Storage Temperature and Humidity: These factors significantly impact fruit shelf life. Research by [5] proposes a system that uses machine learning to predict mango shelf life based on a combination of fruit image analysis and storage temperature.

IV. EXECUTION

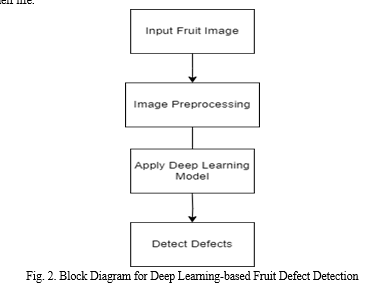

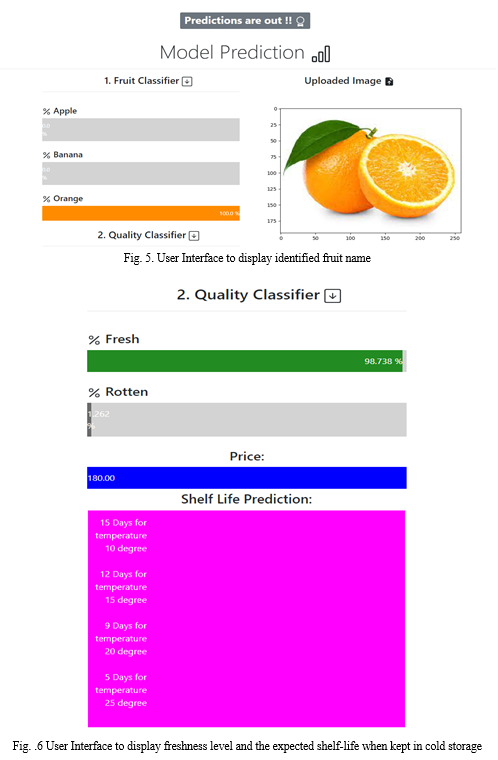

This project proposes a two-step approach for predicting fruit shelf life, leveraging machine learning and computer vision techniques. Here's a breakdown of the execution plan:

A. Data Acquisition and Preprocessing

- Fruit Image Dataset: A diverse dataset of fruit images is collected, encompassing various types, ripeness stages, and qualities. Images are captured under controlled lighting conditions to ensure consistency. Annotations will be added to the images, indicating the fruit type and corresponding freshness level (e.g., ripe, unripe, overripe).

B. Freshness Assessment Model Development

- Machine Learning Model Selection: A convolutional neural network (CNN) is a strong candidate due to its effectiveness in image recognition tasks. The chosen model is pre-trained on a large image dataset like ImageNet to leverage existing knowledge and improve training efficiency.

- Feature Engineering: Image pre-processing techniques like resizing, normalization, and color space conversion are applied for consistency. Relevant features are extracted from the images, including color statistics (mean, standard deviation), texture analysis (smoothness, roughness), and potential shape features (depending on fruit type).

- Model Training: The pre-trained CNN model is fine-tuned on the prepared fruit image dataset with corresponding freshness labels. Training involves optimizing the model's weights and biases to minimize prediction errors for unseen fruit images.

- Model Evaluation: The trained model's performance is evaluated on a separate test dataset to assess its accuracy in predicting fruit freshness levels. Metrics like classification accuracy, precision, and recall are used for evaluation.

C. Shelf-Life Prediction Model Development

- Data Integration: The predicted freshness level from the first model gets combined with real-time sensor data (storage temperature & humidity) obtained from the cold storage system.

- Model Selection and Training: A second machine learning model, a regression model, is trained to predict remaining shelf life based on the combined data. Historical data are also used for training, linking fruit type, initial freshness level, storage temperature, and recorded shelf life until spoilage

- Model Evaluation: The trained model's performance is evaluated on a separate dataset to assess its accuracy in predicting remaining shelf life. Metrics like mean squared error (MSE) or mean absolute error (MAE) are used for evaluation.

By following these steps, this project aims to develop a robust and practical system for fruit shelf-life prediction using machine learning and computer vision. This system has the potential to significantly reduce fruit waste within the food supply chain, promoting sustainability and economic benefits.

V. TOOLS AND TECHNOLOGIES USED

The algorithm development and implementation were carried out using Python programming language due to its extensive libraries and frameworks for machine learning. Libraries such as scikit-learn, TensorFlow, and Keras were utilized for data preprocessing, model development, and training.

- Keras: Keras is a high-level deep learning API written in Python. It is built on top of the machine learning platform TensorFlow. It was developed with a focus on enabling fast trial and furnishing a pleasurable inventor experience. It is specifically designed for humans to work with, not machines. It offers simple, user-friendly tools that reduce cognitive load and provides clear messages. [7]

- TensorFlow: TensorFlow is an open-source, end-to-end framework for machine literacy. With its extensive, adaptable ecosystem of tools, libraries, and community resources, experimenters may advance the state-of-the-art in machine learning while creators can easily create and implement ML-powered activities. Researchers and innovators from Google Brain's Machine Intelligence Battalion created TensorFlow in the beginning to explore machine learning and neural networks. However, the frame is adaptable enough to be applied elsewhere as well. TensorFlow offers reliable Python and C APIs in addition to a backwards-compatible API that is not guaranteed. [8]

- Numpy: The core Python library for scientific computing is called NumPy. A multidimensional array object, different derived objects (like masked arrays and matrices), and a variety of routines for quick array operations—like sorting, selecting, I/O, discrete Fourier transforms, basic linear algebra, basic statistical operations, random simulation, and much more—are all provided by this Python library. [9]

Conclusion

This project explored the potential of machine learning and computer vision for fruit shelf-life prediction. The proposed two-step approach utilizes a CNN model for freshness assessment based on fruit image analysis and a secondary model for shelf-life prediction by integrating freshness level with storage temperature data. This approach offers efficiency, scalability, data driven insights, and improved decision making. The successful implementation of this project can contribute significantly to reducing food waste in the fruit industry, promoting sustainability and economic benefits for producers, retailers, and consumers. While this project establishes a foundation for fruit shelf-life prediction, there\'s room for further development which includes expanding fruit variety, considering external factors, incorporating advanced neural networks, real-time fruit monitoring, and integration with supply chain management. By incorporating these enhancements and conducting field trials in real-world storage environments, this project\'s approach has the potential to become a powerful tool for minimizing fruit waste and optimizing fruit freshness throughout the food supply chain.

References

[1] Food and Agriculture Organization of the United Nations. (2011). Global food losses and food waste. https://www.fao.org/newsroom/detail/FAO-UNEP-agriculture-environment-food-loss-waste-day-2022/en [2] Kader, A. A. (2002). Postharvest biology and technology of horticultural crops. Academic press [3] Ya, E., & Sun, D.-W. (2008). Hyperspectral imaging for assessing the quality of fruits and vegetables. Sensors, 8(6), 3996-4010 [4] Kader, A. A. (2003). Modified atmosphere packaging to maintain fruit quality. In Postharvest handling of fruits and vegetables (pp. 393-418). Woodhead Publishing [5] Grand View Research. (2021, December). Global Fruit Market Size, Share & Trends Analysis Report By Type (Citrus Fruits, Tropical Fruits, Pome Fruits, Stone Fruits, Berries), By Distribution Channel (Supermarkets & Hypermarkets, Convenience Stores, Online Retail), By Region, And Segment Forecasts, 2022-2025 [6] Food and Agriculture Organization of the United Nations. (2011). Global food losses and food waste. https://www.fao.org/newsroom/detail/FAO-UNEP-agriculture-environment-food-loss-waste-day-2022/en [7] KERAS TEAM https://github.com/keras-team/keras [8] TENSORFLOW https://github.com/tensorflow/tensorflow [9] NUMPY https://numpy.org/doc/stable/user/whatisnumpy.html [10] Developing an Information System to Predict the Shelf Life of Food Products: Juwita Juwita; N.M. Erfiza; Viska Mutiawani; Muhammad Ichsan https://ieeexplore.ieee.org/document/9573573 [11] Real-Time Monitoring System for Shelf Life Estimation of Fruit and Vegetables https://www.researchgate.net/publication/340351395_Real-Time_Monitoring_System_for_Shelf_Life_Estimation_of_Fruit_and_Vegetables

Copyright

Copyright © 2024 Sowmiya R, Sujana Chanstar T, Safiya Banu S, Arun Kumar R. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET59163

Publish Date : 2024-03-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online